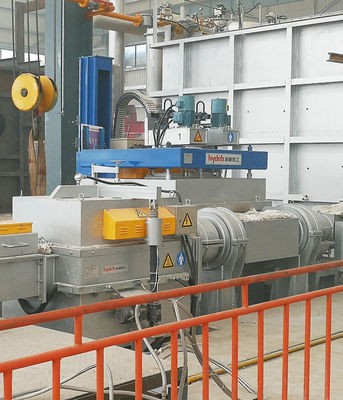

Geavanceerde oplossing voor het ontgassen van aluminium voor een superieure metaalkwaliteit

De HYDEB XCP210-1 Aluminium ontgasmachine is met precisie ontworpen voor optimale raffinage van gesmolten aluminiumlegeringen.dit geautomatiseerde systeem bereikt een uitzonderlijke ontgassingsdoeltreffendheid van 30%Met een capaciteit van 200 kg en volledig instelbare verwerkingscycli (0-99 minuten) levert het een consistentkwalitatief hoogwaardige resultaten voor veeleisende toepassingen op het gebied van gietgieten en gieterij.

Belangrijkste kenmerken en voordelen

- Superieure ontgassingsdoeltreffendheid: verwijdering van 30% waterstof met een eindgehalte ≤ 0,12 ml/100 g-Al

- Hoge zuiverheid gas systeem: compatibel met stikstof of argon (zuiverheid ≥ 99,996%)

- 200 kg verwerkingscapaciteit: ideaal voor de productie op middelgrote schaal

- Volledig geautomatiseerde werking: PLC-besturing met minimale handmatige interventie

- Robuuste constructie: 200 kg gewicht per eenheid met Sic-nitride beschermbuis

- Energie-efficiënt ontwerp: driefasige stroomvoorziening met geoptimaliseerd verbruik

- Aanpasbare verwerking: 0-99 minuten aanpasbare ontgassingscycli

- Eénrotorsysteem: ontwerp met vier lemmen voor efficiënte gasdispersing

Technische specificaties

| Parametercategorie |

Specificatie |

Notities |

| Basisinformatie |

Model: XCP210-1

Afkomst: China |

HYDEB-merk

ISO CE-gecertificeerd |

| Prestatiegegevens |

Efficiëntie van het ontgassen: 30%

Verwerkingscapaciteit: 200 kg

Ontgassingstijd: 0-99 min verstelbaar |

Waterstof ≤ 0,12 ml/100 g-Al

Middelgrote productie

Precieze procescontrole |

| Structuurontwerp |

Aantal rotoren: enkelvoudig

Beschermingsbuis: Sic-nitride

Gewicht van de machine: 200 kg |

4-blad ontwerp

Verbeterde duurzaamheid

Stabiele constructie |

| Operatie |

Operatiemodus: volledig automatisch

Stroomvoorziening: driefasige vierdraad

Type machine: gietmachine |

Minimale handmatige ingreep

Stabiel vermogen |

| Kwaliteitsborging |

Garantieperiode: 1 jaar

Certificering: ISO CE |

Alomvattende dekking

Internationale normen |

Toepassingen

Ideale oplossing voor de precisieverwerking van aluminium

Optimaal ontworpen voor:

- Vervaardiging van aluminiumlegeringen

- Smeltebehandeling vóór extrusieprocessen

- Ontgassing bij de vervaardiging van hoogwaardige aluminiumproducten

- Raffinage van aluminiumlegeringen voor de lucht- en ruimtevaart- en automobielindustrie

- Kwaliteitsverbetering bij de verwerking van gerecycled aluminium

Aanpassingsdiensten

Flexible configuratie voor uw productiebehoeften

HYDEB biedt aanpassingsmogelijkheden zoals:

- Aanpassing van de verwerkingscapaciteit (bereik 100-500 kg)

- Optimalisatie van de specifieke rotorconfiguratie

- Aanpassing van het automatiseringsniveau (semi/volledig automatisch)

- Aanpassing van het gasvoorzieningssysteem

- Taal van de besturingsinterface en aanpassing van het apparaat

Informatie over bestellingen

| Artikel 1 |

Detail |

| Minimale bestelhoeveelheid |

1 eenheid |

| Eenheidsprijs |

13.000 dollar per set |

| Verpakking |

Versterkte houten doos |

| Leveringstermijn |

50-60 dagen |

| Betalingsvoorwaarden |

30% aanbetaling + 70% bij levering |

| Jaarlijkse levercapaciteit |

1, 000 eenheden |

Technische ondersteuning en diensten

Uitgebreid klantenservice-systeem

- Installatiehandleiding: gedetailleerde handleidingen en video-instructies

- Operatietraining: opleidingen ter plaatse of op afstand

- Technische raadpleging: deskundig team voor procesoptimalisatie

- Voorziening met onderdelen: Originele onderdelen met snelle levering

- Onderhoudsdiensten: regelmatig onderhoud en prestatiecontroles

Verpakking en verzending

- Professionele verpakking: schok- en vochtbestendige houten kratten

- Verzendingsopsporing: real-time logistieke opsporingsinformatie

- Verzekeringsmogelijkheden: facultatieve vervoersverzekeringsdiensten

- Douaneondersteuning: volledige uitvoerdocumentatie en bijstand bij de inklaring

Vaak gestelde vragen

V1: Voor welke productieschaal is deze ontgassering geschikt?

A: Het XCP210-1 model is ontworpen voor kleine tot middelgrote aluminiumverwerkingsfaciliteiten. De 200 kg capaciteit voldoet aan de meeste productievereisten en biedt een uitstekende ROI.

V2: Welke specificaties voor de gasvoorziening zijn vereist?

A: De apparatuur is compatibel met stikstof of argon van hoge zuiverheid (zuiverheid ≥ 99,996%).

V3: Welke installatievoorwaarden zijn vereist?

A: Het vereist een driefasige vierdraad 380V voedingsvoorziening, perslucht (0,6-0,8 MPa), een vlakke en stevige basis en een compliant gasvoorziening.

V4: Wat is de frequentie van het onderhoud?

A: Aanbevolen slijtagecontrole van de rotor om de 3 maanden, uitgebreide inspectie van elektrische en mechanische systemen om de 6 maanden.Beschermingsbuis met sicnitride heeft een duur van 6-12 maanden, afhankelijk van de gebruiksfrequentie..

V5: Kan het andere niet-ijzeren metalen verwerken?

A: Deze machine is geoptimaliseerd voor aluminiumlegeringen. Voor andere metalen (magnesiumlegeringen, koperlegeringen) raadpleegt u ons technische team voor een aangepaste configuratie.

ISO CE-gecertificeerde kwaliteitsborging

Alle HYDEB-apparatuur ondergaat strenge kwaliteitscontroleprocedures en is ISO CE-gecertificeerd, waardoor de naleving van internationale veiligheids- en prestatienormen wordt gewaarborgd.Onze garantie van één jaar zorgt voor volledige gemoedsrust voor uw investering..

Klaar om de kwaliteit van uw aluminiumverwerking te verbeteren?

Neem vandaag nog contact op met ons technisch team voor:

- Gedetailleerde technische specificaties

- Op maat gemaakte oplossingen

- Fabrieksprijzen

- Case studies en referenties

- Demonstratieprocedures ter plaatse

HYDEB Thermal Tech is uw partner in het verwerken van aluminium

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!