Keramische schuimfilter

Een gesmolten aluminiumfiltratiebox is een vuurvaste kamertje dat is geïntegreerd in het stroompad van gesmolten metaal (meestal tussen de oven en de gietunit).Keramische schuimfilter (CFF), een poreus keramisch plaatje dat is ontworpen om niet-metalen insluitsels (zuiverheden) fysiek te vangen wanneer er gesmolten aluminium doorheen wordt gegoten.

Dit systeem is een essentiële en standaardtechnologie in moderne aluminiumgieterijen en gieterijen voor de productie van kwalitatief hoogwaardige, gebrekvrije gietproducten.

Doel en waarom het noodzakelijk is

Gesmolten aluminium bevat altijd vaste onzuiverheden dieInklusiesDeze omvatten:

- Oxiden:(Al2O3) door oppervlakte-oxydatie tijdens het smelten en overbrengen.

- Spinel:Complexe oxiden die vaak magnesium bevatten.

- met een gewicht van niet meer dan 10 kgVan bekleding of gereedschap.

- vuurvaste deeltjes:Erosie door ovenvoeringen en -troggen.

- Clusters:Agglomeraties van deze deeltjes.

Als deze insluitsels niet worden verwijderd, leiden deze tot:

- Slechte afwerking.

- Verminderde mechanische eigenschappen (sterkte, ductiliteit).

- Porositeit en gebreken in eindproducten.

- Catastrofale storingen in hoogwaardige toepassingen zoals lucht- en ruimtevaart of auto-onderdelen.

De CFF-doos is de meest efficiënte en veelgebruikte methode om deze insluitsels te verwijderen.

Belangrijke onderdelen van het filtratiesysteem

Een typisch systeem bestaat uit drie hoofdonderdelen:

1. Filterbox (of Filter Casse):

- Een robuuste stalen doos die zwaar is bekleed met vuurvaste cement of vooraf gegoten vuurvaste panelen.

- Ontworpen om gesmolten aluminium vast te houden en bestand te zijn tegen thermische schokken en chemische corrosie.

- Heeft een inlaatput (waar metaal binnenkomt) en een uitlaatput (waar gefilterd metaal uitgaat).

- Vaak is er een verwarmingssysteem (gas of elektriciteit) om het bevriezen van metaal te voorkomen.

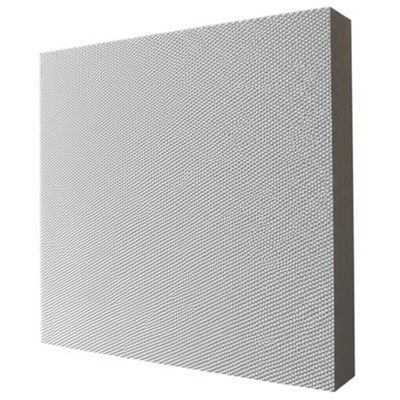

2. Het keramische schuimfilter (CFF):

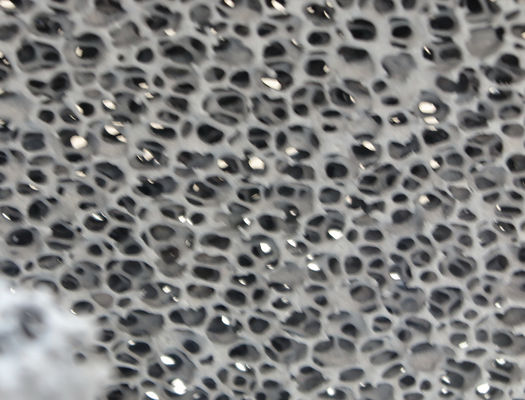

Het hart van het systeem is een driedimensionale, open cel schuimstructuur gemaakt van materialen zoals:

- Aluminium (Al2O3)

- Zirkonium (ZrO2)

- Siliciumcarbide (SiC)

Het wordt gekenmerkt door dePoren per centimeter (PPI):

- 10-20 PPI:Grove filtratie voor ruwe toepassingen.

- 30-50 PPI:Het meest voorkomende bereik voor algemeen gieten (bijv. extrusiebilletten, gietingen).

- 50-80 PPI:Fijne filtratie voor hoogwaardige producten zoals luchtvaartplaten, folie en kritische gietstukken.

De filters zijn broos en moeten voor het gebruik zorgvuldig worden behandeld.

3Het filterpakket en het afdichtingssysteem:

- Een keramische papierpakking met hoge temperatuur wordt tussen het filter en de rand van de doos geplaatst.

- Eenvasthoudingsstraalof vuurvaste klem wordt gebruikt om het filter op deze pakking te drukken, waardoor een afdichting ontstaat diealleHet gesmolten metaal moet door het filter stromen, niet eromheen.

Hoe het werkt: Het filteren

Het proces is voornamelijkdiepbeddensuivering, waarbij twee hoofdmechanismen betrokken zijn:

1Mechanische zeven:

Grote insluitsels en clusters worden fysiek geblokkeerd op het oppervlak van het filter omdat ze groter zijn dan de poriën van het filter.

2Dieptefiltratie:

Naarmate er zich op het oppervlak een koek van insluitsels opbouwt, wordt het zelf een filterlaag.

Kleine insluitsels zijn gevangen.binnenhet complexe driedimensionale netwerk van de filtercellen door middel van mechanismen voor:

- Interceptie:Deeltjes raken aan de filterwanden en kleven aan.

- Brownian diffusie:Zeer fijne deeltjes drijven af en botsen met de celwanden.

- Gravitatieve sedimentatie:Deeltjes komen op celwanden terecht.

- Inertiële impaktie:Deeltjes kunnen niet het bochtige stroompad volgen en het keramische materiaal raken.

Deze combinatie zorgt voor een uiterst hoge filtratie-efficiëntie, vaak > 95%.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!