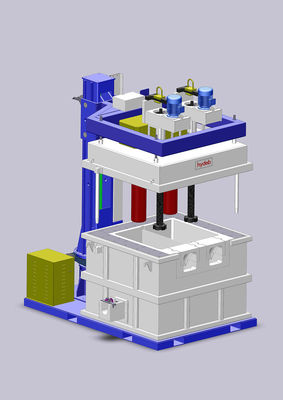

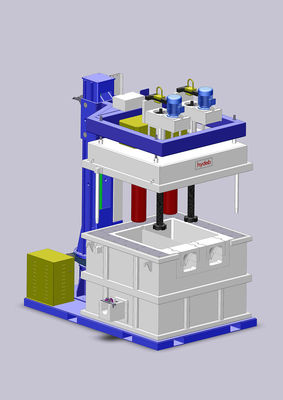

Product Description:

The Rotary Degassing Unit is a crucial piece of equipment for the efficient processing of molten aluminium in industrial settings. Specifically designed as a Box Type In-line Rotary Degassing Unit, this product offers exceptional performance in impurity removal and enhancing the overall quality of the final aluminium product.

Key features of the Rotary Degassing Unit include:

Cooling Water Pressure:

0.2-0.4 MPa - The unit is equipped to operate effectively within this range of cooling water pressure, ensuring optimal performance and longevity.

Gas Consumption:

10-15 L/min - The unit efficiently consumes gas within this range, striking a balance between effective degassing and cost efficiency.

Max Pressure:

0.1MPa - With a maximum pressure capacity of 0.1MPa, the unit can effectively handle the degassing process without compromising on safety.

Gas Inlet Pressure:

0.4-0.6 MPa - The unit is designed to work within this range of gas inlet pressure, ensuring consistent and reliable operation.

Capacity:

500-1000 Kg/h - The unit's capacity to process molten aluminium within this range makes it suitable for medium to large-scale industrial operations.

Overall, the Rotary Degassing Unit is a reliable and efficient solution for enhancing the quality of molten aluminium by effectively removing impurities. Its Box Type In-line design ensures ease of integration into existing production lines, making it a valuable addition to any aluminium processing facility.

Features:

-

Product Name: Rotary Degassing Unit

-

Degass Efficiency: 60%

-

Gas Inlet Pressure: 0.4-0.6 MPa

-

Max Pressure: 0.1MPa

-

Gas Type: Argon

-

Cooling Water Consumption: 5 L/min

Technical Parameters:

|

Cooling Water Pressure

|

0.2-0.4 MPa

|

|

Degassing Time

|

Adjustable

|

|

Total Power Kw

|

<47

|

|

Power Supply

|

380V/50Hz

|

|

Degass Efficiency

|

60%

|

|

Max Pressure

|

0.1MPa

|

|

Max Temperature

|

1500℃

|

|

Gas Type

|

Argon

|

|

Dimension

|

1200mm X 800mm X 1500mm

|

|

Gas Inlet Pressure

|

0.4-0.6 MPa

|

Applications:

The Hydeb BDU Rotary Degassing Unit is an essential equipment used for the removal of impurities and hydrogen in various metal processing applications. This advanced unit is designed to cater to a wide range of product application occasions and scenarios due to its high efficiency and reliable performance.

Originating from China, the Hydeb BDU boasts ISO CE certification, ensuring its quality and adherence to international standards. With a minimum order quantity of 1, this product is suitable for both small-scale and large-scale metal processing operations.

With a price exceeding $30,000USD, the Hydeb BDU comes packaged in a sturdy wooden box for secure transportation. The delivery time for this product ranges from 50 to 60 days, providing customers with a reasonable waiting period.

Customers can avail of flexible payment terms of 30%+70% when purchasing the Hydeb BDU, making it convenient for budget planning. The unit has a supply ability of 500 sets per year, ensuring availability for various industrial needs.

The Hydeb BDU Rotary Degassing Unit has a robust capacity ranging from 500 to 1000 Kg/h, making it suitable for processing different quantities of metal. The cooling water pressure required for operation falls between 0.2 to 0.4 MPa, ensuring optimal performance.

Powered by electricity with a power supply of 380V/50Hz, the Hydeb BDU is efficient and reliable in impurity removal and hydrogen removal processes. The cooling water consumption of 5 L/min ensures adequate cooling for continuous operations.

Support and Services:

The Rotary Degassing Unit is a high-quality product designed to remove dissolved gases from molten metal effectively. Our Product Technical Support team is available to assist you with any inquiries regarding the installation, operation, and maintenance of the unit. Additionally, we offer comprehensive services to ensure the optimal performance and longevity of your Rotary Degassing Unit.

Packing and Shipping:

Product Packaging for Rotary Degassing Unit:

The Rotary Degassing Unit is carefully packaged in a sturdy cardboard box to ensure safe delivery. The unit is securely wrapped in protective packaging material to prevent any damage during transport.

Shipping Information:

Orders for the Rotary Degassing Unit are shipped via a trusted courier service within 1-2 business days after payment confirmation. Customers will receive a tracking number to monitor the status of their shipment. Delivery times may vary depending on the destination, with estimated delivery within 5-7 business days for most locations.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!